Electronic precision instruments are essential tools in modern manufacturing and production processes. These instruments, which include devices such as electronic measuring tools, sensors, and testing equipment, provide highly accurate data that is crucial for quality control and operational efficiency. The importance of these instruments cannot be overstated, as they play a vital role in enhancing productivity, reducing waste, and ensuring compliance with industry standards.

One of the primary benefits of electronic precision instruments is their ability to enhance quality control. In industries such as aerospace, automotive, and pharmaceuticals, where even the slightest deviation from specifications can lead to significant safety risks or financial losses, precision measurement is paramount. Electronic instruments, like digital calipers and laser measuring systems, offer rapid and accurate measurements that enable manufacturers to detect discrepancies early in the production process. This proactive approach minimizes the risk of defective products reaching the market, thereby protecting brand reputation and customer trust.

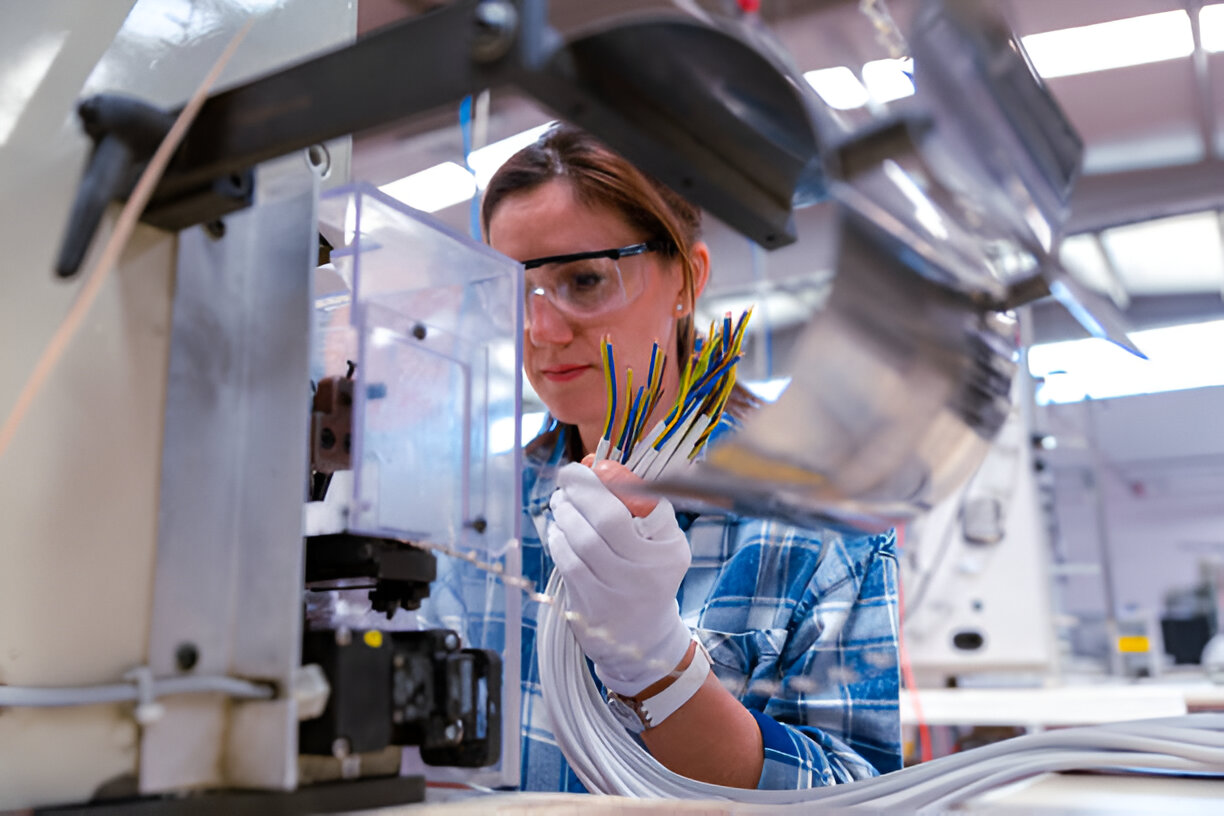

Moreover, electronic precision instruments facilitate automation in manufacturing processes. Many modern production environments rely on automated systems that require precise data inputs to function correctly. Instruments like automated gauging systems and digital data loggers provide real-time feedback, enabling machines to adjust operations dynamically. This not only boosts productivity but also optimizes resource usage, leading to lower operational costs and increased profitability.

Additionally, the integration of electronic precision instruments in industries supports innovation and research and development (R&D) efforts. Accurate measurements are critical for testing new materials, products, and processes. As industries strive to innovate and improve their offerings, having access to reliable precision instruments allows engineers and scientists to experiment with confidence. This fosters an environment where new technologies can flourish, driving progress across various sectors.

In conclusion, electronic precision instruments are indispensable in the industrial landscape. They enhance quality control, support automation, and drive innovation, contributing to overall efficiency and productivity. As industries continue to evolve, the role of these instruments will only become more significant, underscoring their critical importance in maintaining competitive advantage.